Guide to Analyzing Sandstone Samples

The Canstrat guide to analyzing sandstone samples is a repeatable process that will help insure the geologist does not miss any important characteristics of the rock. Users of this guide should note this is not a replacement for hands on training with an experienced geologist in drill cutting sample analysis. Observing drill cuttings through a microscope is a practiced skill and requires a solid foundation of geology to be successful.

Learn how to use the Canstrat Method on real world samples.

Step 1: Observe bulk sample

The first step is to observe the bulk sample in the tray without a microscope or at very low magnification. Key features can be picked out before detailed examination begins which can help with further analysis.

- What is the colour of the sample?

- What is the sample made up of? I.e. shales, sands, silts, carbonates, lost circular material?

- Does the sample smell of petroleum?

Another very effective way to do this is to have several samples in a 5 or 10 compartment sample tray. In the sample below there is a gradual increase in sand and silt grains going from left to right. Even before this sample goes under the microscope the geologist will know to expect more sand or silt. Do not use too much sample, a teaspoon is plenty to observe the sample correctly.

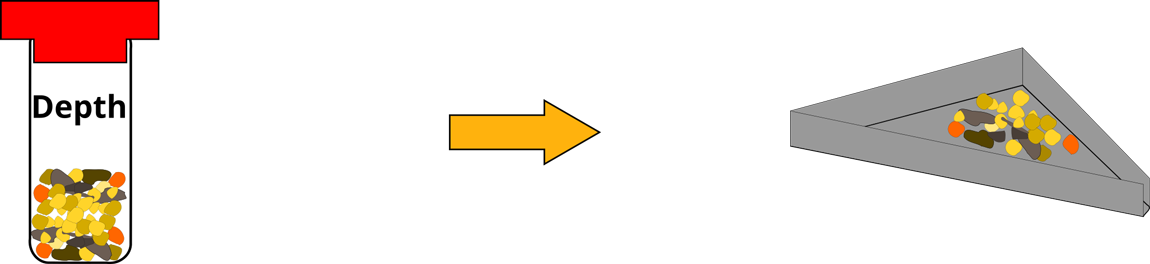

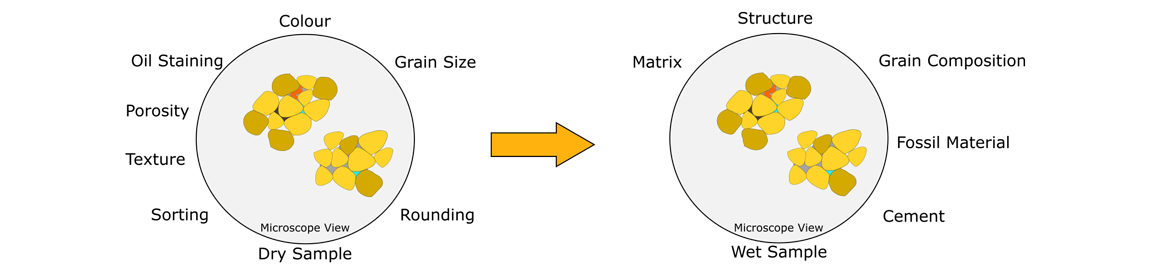

Step 2: Examine and Select

For proper analysis it is vitally important the geologist be able to recognize the dominant rock type in the sample. On two watch glasses place several grains of the dominant rock type for testing. Select one of the watch glasses to begin detailed analysis of the sample. 2-2.5x magnification is the recommended setting for the first pass of a sample. Increasing the magnification is necessary to examine some features in more detail such as porosity or texture.

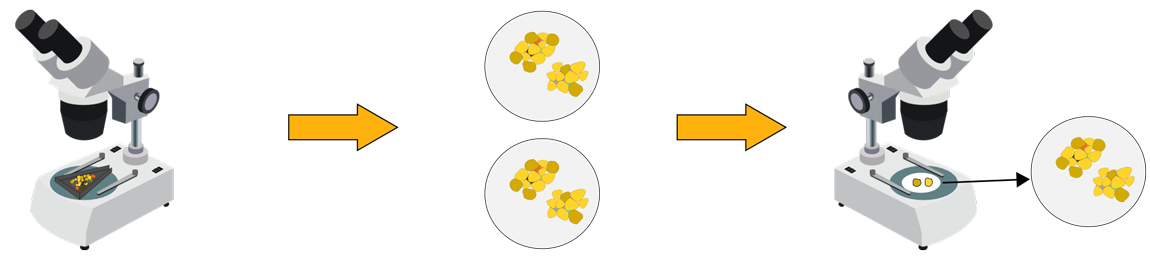

Step 3: Record Rock Properties

Begin by examining the sample dry for the following properties: colour, grain size, rounding and sorting, porosity, textures, and oil staining. Next wet the sample with just enough water to cover the sample and observe: matrix, structures, grain composition, fossil material, and cement.

Once all the properties have been recorded dab the sample with some tissue paper to absorb as much water as possible without the drill cuttings becoming stuck on the tissue paper. Put this sample aside for further examination.

Grainsize cards are an excellent way to help with determining grain size, rounding and sorting.

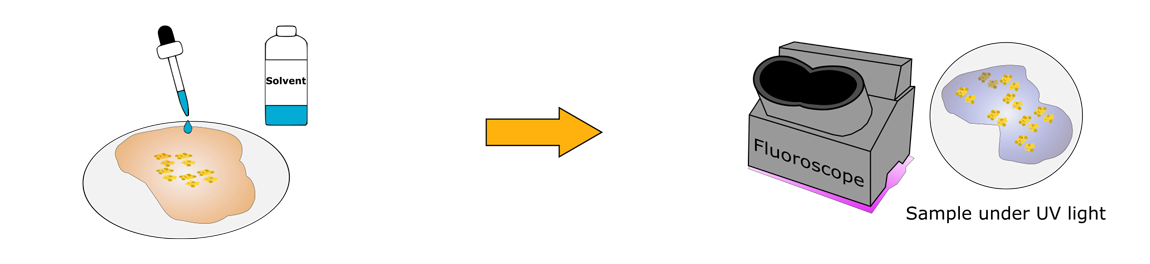

Step 4: Cut and Fluorescence

Grab the dry watch glass sample and place several grains into a spot plate if available, or keep them in the watch glass.

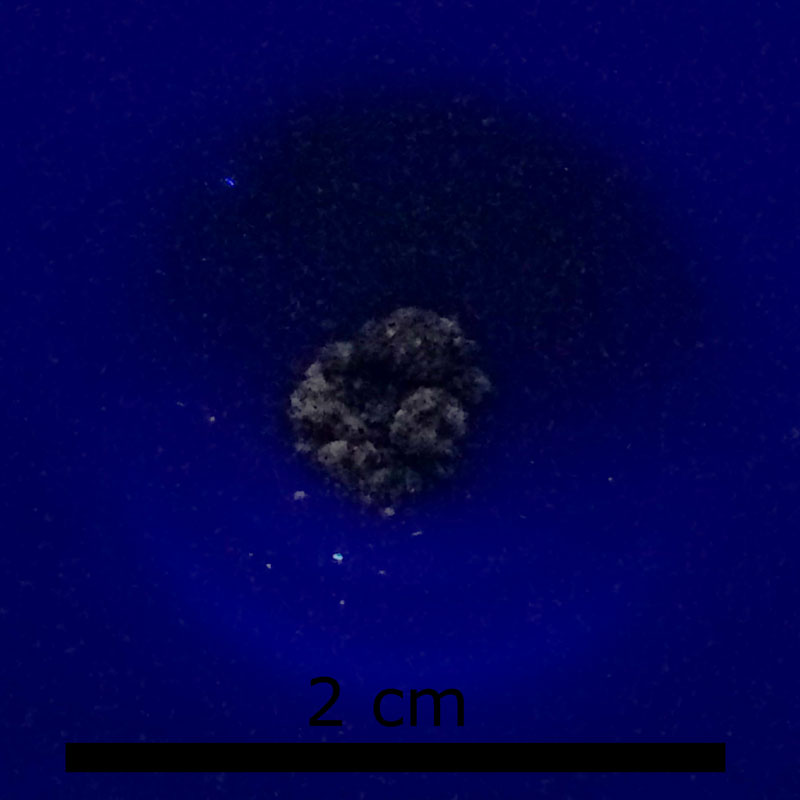

Look at the sample dry under UV light and record the dry fluorescence colour and its distribution such as rare, spotty, even etc. Fluorescence will appear due to oil staining on the surface of grains, sometimes minerals or fossils present will also fluoresce.

This example shows spotted yellowish orange dry fluorescence.

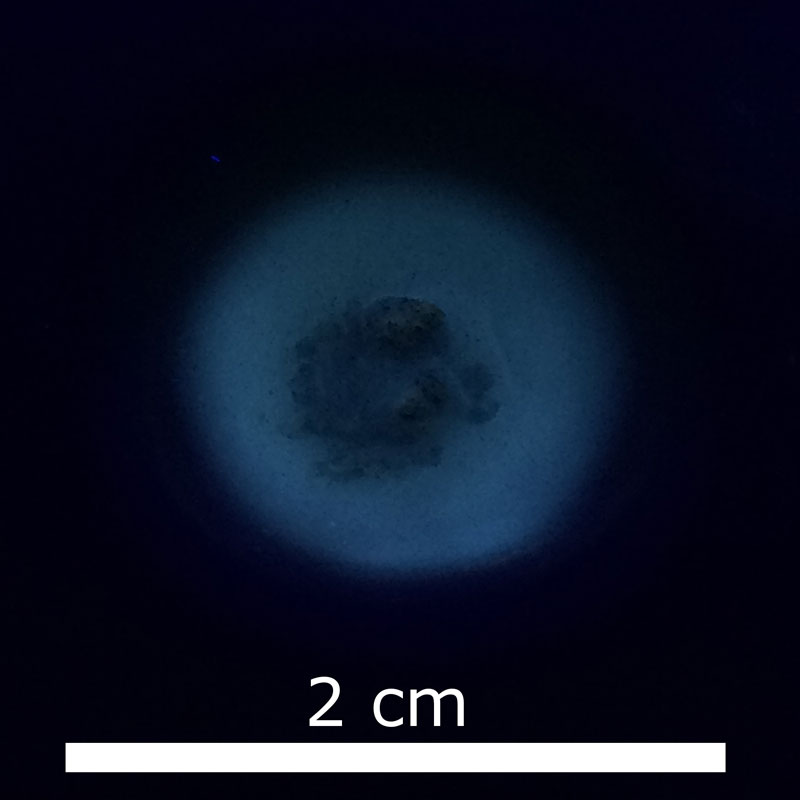

Apply solvent to the sample and record the cut. Generally cut is recorded as dark, medium, light and clear, from the colour of the solvent. In this example, you can see a medium cut forming a ring in the spot plate as the solvent evaporates around the grains being tested.

Fluorescence is recognized as the solvent fluid colour change under black light due to UV reactions with the hydrocarbons present. Record if the fluorescence is poor, fair, or good. Also record the nature of the fluorescence such as slow, streaming, and instant.

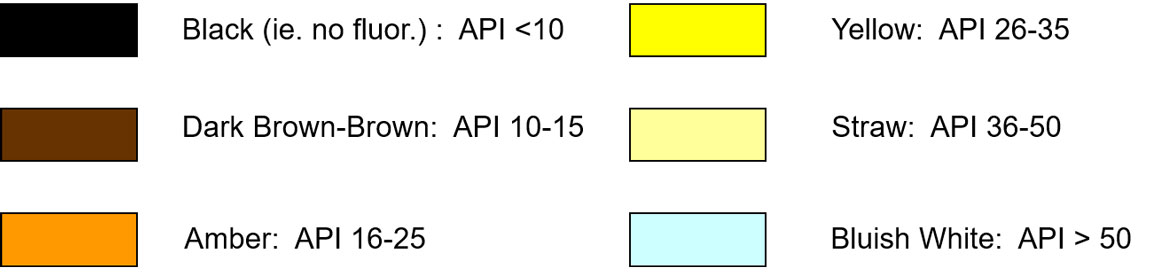

This sample would be described as instant good bluish white fluorescence. Colour can give an indication to the api of hydrocarbons present.

If the sample shows fluorescence but does not produce a cut or liquid fluorescence when solvent is applied it may just be the minerals or fossils present giving you a false positive.

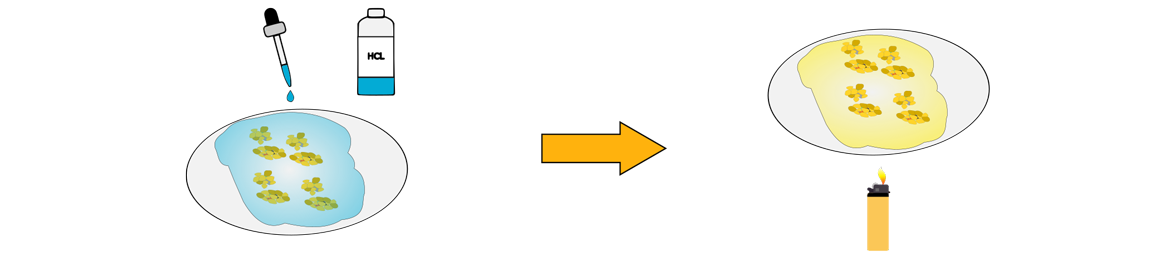

Step 5: Testing for Carbonate Cements

Applying a few drops of 10% concentration HCL will reveal if there are any carbonate materials present. Calcite cement will effervesce quickly and vigorously with HCL. Calcareous fossil fragments will also effervesce quickly, pay close attention to what part of the sample is reacting. If the reaction is slow then dolomite cement may be present, heat the sample up and if the effervescence increases dolomite is likely to be the cement. If the acid turns yellow after being heated, this is a sign of siderite being present. Determining carbonate cement percentage is a combination of observing the cement before, during, and after testing with HCL and is a practiced skill.

Step 6: Estimate Induration

If the drill cuttings are still cemented after heating in HCL, then suspect anhydrite or silica cement. If anhydrite is present the sample will crush easily with a glass rod and acicular crystals will form on the edge of the watch glass where the HCL evaporated.

Silica cement is insoluble in HCL and makes the rock difficult to crush depending on how much silica cement is present. Quartz overgrowths will be observed at 10% silica cement, at 20% the sand will offer good resistance, at 30% it will be almost impossible to crush without splintering.

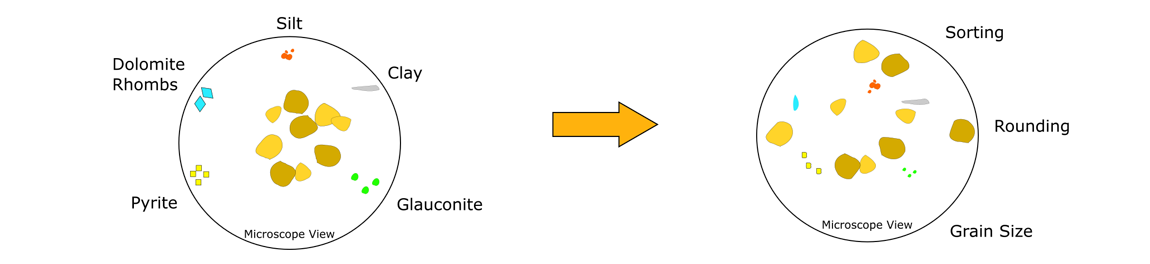

Step 7: Observe Insoluble material and do a final check

Once the sample has been broken apart view any insoluble material at the bottom of the watch glass. Lastly do a final check of sorting, rounding and grainsize.

By following these steps every time all the important information for sandstone drill cuttings will be captured. For information on how to analyze shale, limestone, dolomite, anhydrite and siltstone check out our learning center.